- Home Page

- Company Profile

-

Our Products

- Special Purpose Machine

- MACHINING FIXTURE- HMC

- FITUP FIXTURE - OHT - BODY DUMPER - CATERPILLAR

- ROBOTIC LASER CUTTING MACHINE

- FITUP FIXTURE - DUMPER - LMT - SUB ASSEMBLY

- ROBOTIC WELDING AUTOMATION POSITIONER

- ROBOTIC WELDING FIXTURES- POSITIONERS-MANIPULATORS

- TYRE ASSEMBLY EQUIPMENT - ONLINE - EARTHMOVER - CATERPILLAR

- MANUAL FITUP FIXTURE

- MANUAL FITUP FITURE

- THREE JAW SELF CENTERING LOCTOR WITH CHUCK

- FITUP FIXTURE - MANUAL - DUMPER HANDRAIL

- HYDRAULIC FITUP FIXTURE UPPER FRAME CENTER SECTION

- WELDING FIXTURE - DUMPER LADDER

- 789 Giant Mining Truck Boring Special Purpose Machine

- ROBOTIC LASER CUTTING MACHINE

- BORING SPM - MULTI MODEL - DUMPER BODY - LMT

- BORING SPM - MULTI MODEL- DUMPER BODY - OHT

- MECHANICAL FIXTURE - FITUP - ASSEMBLY

- FITUP FIXTURE - DUMPER - SUB ASSEMBLY

- FITUP FIXTURE DUMPER SUB ASSEMBLY - OHT - LMT

- FITUP FIXTURE - DUMPER - OHT PARTS

- HYDRAULIC FITUP FIXTURE - UPPER FRAME MULITIMODEL

- FITUP FIXTURE -HYDRAULIC - DOOSAN BOBCAT - SSL -S70

- ASSEMBLY PNEUMATIC FIXTURE -BUS CHASSIS - DAIMLER

- FITUP FIXTURE - DUMPER LADDER

- Welding Positioner

- Welding Positioner with Adaptors for Multi Model - SAW

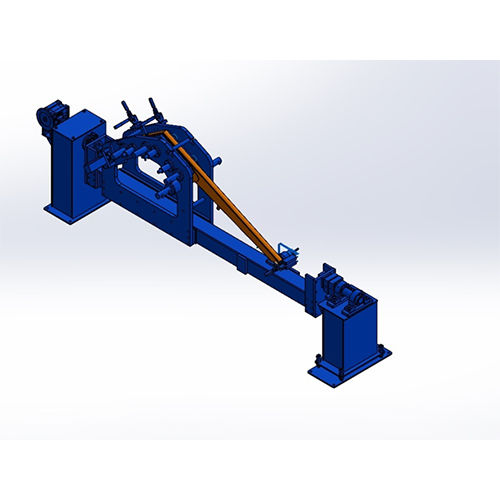

- Welding Positioner - Dump Truck Frame - Caterpillar

- HYDRAULIC WELDING POSITIONER - BOBCAT S70 MINI SKID STEER LOADER

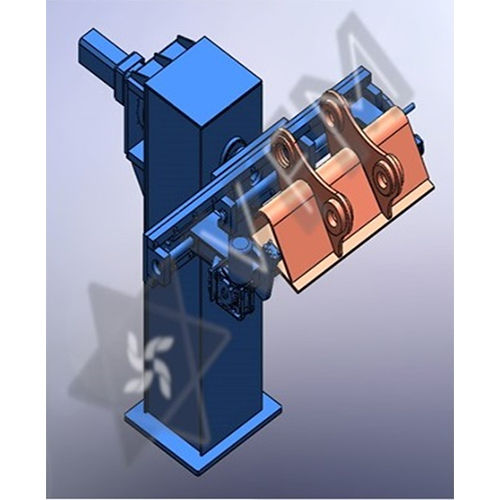

- WELDING POSITIONER HINGE ASSEMBLY BUCKET

- WELDING POSITIONER WITH ADAPTOR-360 DEGREE ROTATION 4000MM VERTICAL TRAVEL

- WELDING POSITIONER - BOBCAT S70 MINI SKID STEER LOADER

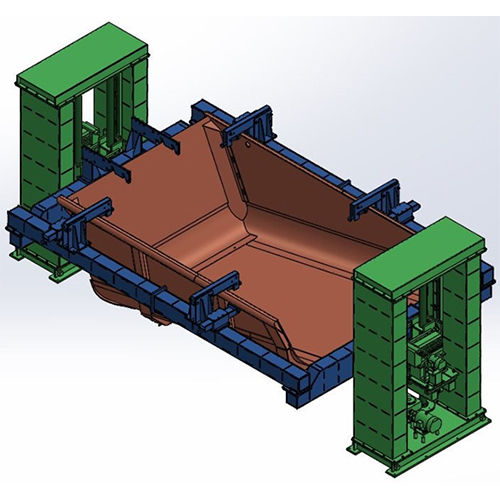

- Giant Mining Truck Dumper Body Welding Positioner

- Mining Truck Dumper Body Welding Positioner

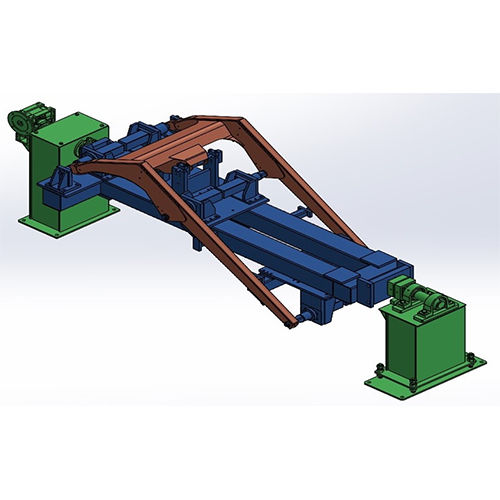

- Mining Truck Chassis Rail Assembly Multi Model Welding Positioner

- Excavator Boom Multi Model Welding Positioner

- WELDING POSITIONER - 360 DEGREE ROTATION ONLY

- WELDING POSITIONER WITH ADAPTOR COMMON FOR MULTI MODELS 360 DEGREE ROTATION - 2000MM VERTICAL TRAVEL

- WELDING POSITIONER - BOBCAT S70 BACKHOE MINI SKID STEER

- WELDING POSITIONER - BOBCAT S70 MINI SKID STEER

- Hydraulic Fit-up Fixture for Construction Equipmen

- Forming Tool & Die for Press Brake

- Number Marking Machine

- Pneumatic Assembly fixture

- Robotic Welding Automation

- Manual Fit-up Fixtures

- Fuel Tank Cleaning Machine

- Transportation Trolley

- Tyre Mounting Machine for Mining Equipment

- LASER MEASURING EQUIPMENT

- Hydraulic Spinning Machine

- Shock Absorber Testing Machine

- Special Purpose Machine

- Contact Us

WELDING POSITIONER - BOBCAT S70 MINI SKID STEER

Product Details:

- Output Voltage 12V

- Power Consumption 1.5-2.0 kW per cycle

- Welding Rotational/Positioner

- Phase Single Phase

- Current Range Up to 35A

- Equipment Type Welding Positioner for BOBCAT S70 Mini Skid Steer

- Automation Grade Semi-Automatic

- Click to view more

X

WELDING POSITIONER - BOBCAT S70 MINI SKID STEER Product Specifications

- New

- Rotational/Positioner

- Industrial Welding, Fabrication Workshops, Construction Sites

- Diesel

- Single Phase

- Hydraulic Motor

- Length: 2422 mm, Width: 1182 mm, Height: 1875 mm

- 700 kg

- Fixture Plate Diameter: 300 mm

- 50 Hz

- 1.5-2.0 kW per cycle

- 12V DC

- Semi-Automatic

- Welding Positioner for BOBCAT S70 Mini Skid Steer

- Mini Skid Steer Welding Positioner

- 35A

- High Strength Steel

- 12V DC

- 23.5 HP (17.5 kW)

- Up to 35A

- 12V

- Integrated Wheels & Forklift Pockets

- 3-15 RPM (adjustable)

- Emergency Stop Switch, Overload Protection

- Powder Coated

- Universal Clamp

- Approx. 1,100 kg

- Manual and Remote Control

- 700 kg

- 0° to 135°

- 500 mm

Product Description

Purchase the hot-selling WELDING POSITIONER designed for the BOBCAT S70 MINI SKID STEER, a top-drawer solution for industrial welding and fabrication. Built in India with high-strength steel, its extraordinary 700 kg load capacity, adjustable rotation speed, and universal clamp mount make it a hero in any workshop. The affordable, semi-automatic positioner features innovative safety elements, integrated wheels, and a powder-coated finish for durability. Powered by a 23.5 HP hydraulic motor, this new equipment ensures heroic performance for manufacturers and suppliers.

Key Features & Applications

Widely used by fabricators, manufacturers, and construction professionals, the WELDING POSITIONER - BOBCAT S70 MINI SKID STEER offers rotational positioning, table tilt range up to 135, and exceptional versatility with a universal clamp mount. Its application surfaces include fabrication workshops, industrial welding stations, and construction sites where top-tier safety and performance are essential. The ergonomic controls and robust build guarantee reliability across a variety of rugged environments.

Packaging & Market Distribution

Each unit is securely packed to ensure safe outlay during transit, providing peace of mind for buyers. The primary domestic market is India, with major export markets spanning Asia, Africa, and Europe. Products are promptly dispatched to meet client schedules. This welding positioner is trusted by fabricators and suppliers alike for its fast domestic mar delivery and export reliability, consistently matching quality standards in leading industrial regions.

Key Features & Applications

Widely used by fabricators, manufacturers, and construction professionals, the WELDING POSITIONER - BOBCAT S70 MINI SKID STEER offers rotational positioning, table tilt range up to 135, and exceptional versatility with a universal clamp mount. Its application surfaces include fabrication workshops, industrial welding stations, and construction sites where top-tier safety and performance are essential. The ergonomic controls and robust build guarantee reliability across a variety of rugged environments.

Packaging & Market Distribution

Each unit is securely packed to ensure safe outlay during transit, providing peace of mind for buyers. The primary domestic market is India, with major export markets spanning Asia, Africa, and Europe. Products are promptly dispatched to meet client schedules. This welding positioner is trusted by fabricators and suppliers alike for its fast domestic mar delivery and export reliability, consistently matching quality standards in leading industrial regions.

Specification

|

Country of Origin |

Made in India |

|

Color |

Customer choice |

|

Surface Finishing |

Good finish |

|

Product Type |

Welding Positioner |

|

Usage/Application |

Bachkoe / Mini Skid Steer loader |

FAQ's of WELDING POSITIONER - BOBCAT S70 MINI SKID STEER:

Q: How does the welding positioner improve industrial welding efficiency?

A: The positioner provides adjustable rotation speeds and table tilt, enabling precise workpiece positioning. This reduces manual handling, enhances weld accuracy, and increases productivity in fabrication and construction environments.Q: What safety features does the BOBCAT S70 Mini Skid Steer welding positioner offer?

A: Key safety features include an emergency stop switch and overload protection. These safeguards protect operators and equipment during intensive welding operations, ensuring reliable and secure usage.Q: Where is this welding positioner commonly used?

A: This product is frequently used in fabrication workshops, industrial plants, and construction sites-anywhere the BOBCAT S70 Mini Skid Steer loader operates or precision welding tasks are performed.Q: What is the process to operate or control the positioner?

A: Operation is straightforward via manual or remote control. The positioner's semi-automatic system allows users to adjust rotational speed and table tilt, accommodating various workpiece sizes and welding requirements efficiently.Q: How is the product packaged for delivery and export?

A: Welding positioners are meticulously packaged, ensuring protection against damage during transport. They are dispatched to domestic and international locations, maintaining quick and reliable outlay in major markets.Q: What are the main benefits of the equipment's design features?

A: Integrated wheels and forklift pockets provide superior mobility, while the powder-coated finish offers durability. The universal clamp and robust load capacity accommodate diverse workpieces, making this positioner a top-drawer investment for heavy-duty tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email